In the world of precision manufacturing, metal tube laser cutting stands out as a revolutionary process that offers unparalleled accuracy and efficiency. Future Form Manufacturing is at the forefront of this technology, providing top-tier services that cater to diverse industrial needs. This article explores the many benefits of metal tube laser cutting and why Future Form is your go-to partner for these services.

One of the primary advantages of using a metal tube laser cutting machine is its ability to deliver exceptional precision and accuracy. This technology ensures repeatable results, making it ideal for industries where tight tolerances are critical, such as aerospace, automotive, and medical equipment manufacturing. By utilizing computer-controlled lasers, we can achieve intricate designs with minimal errors, ensuring that each cut meets exact specifications. The precision offered by laser cutting not only enhances product quality but also reduces the likelihood of defects. This level of accuracy is particularly beneficial in applications where even minor discrepancies can lead to significant issues. Whether it's creating complex geometries or executing detailed patterns, our laser cutting services ensure consistent excellence.

Another significant benefit of metal tube laser cutting is its ability to minimize material waste. Traditional cutting methods often result in substantial scrap material, which can increase costs and negatively impact sustainability efforts. However, laser cutting creates narrow, precise cuts that maximize material use and reduce waste. Future Form employs advanced nesting technology to ensure efficient material utilization, aligning with sustainable practices and contributing to cost savings. By minimizing waste, businesses can optimize their resources and improve their environmental footprint, making laser cutting an attractive option for companies committed to sustainability.

Metal tube laser cutting machines offer remarkable versatility, accommodating a wide range of materials including steel, aluminum, and copper. This flexibility extends to handling various shapes and profiles, enabling the creation of intricate designs that traditional methods cannot achieve. We leverage this versatility to serve clients across multiple sectors such as transportation, medical infrastructure, exercise equipment and electronics. The ability to adapt to different materials and designs allows businesses to explore innovative solutions and expand their product offerings without compromising on quality or efficiency.

Cost efficiency is another compelling reason to choose metal tube laser cutting. By reducing the need for manual intervention and streamlining production processes, this technology lowers labor costs and accelerates production timelines. Automation also facilitates continuous operation, enabling businesses to meet tight deadlines without sacrificing quality. At Future Form, the integration of automation with laser cutting technology ensures that projects are completed efficiently and economically. This approach not only reduces operational costs but also enhances productivity, allowing businesses to maintain a competitive edge in the market. Future Form has invested in a nitrogen generator that further reduces operating cost by utilizing ambient nitrogen instead of purchasing and vaporizing liquid nitrogen to supply the required cutting gas.

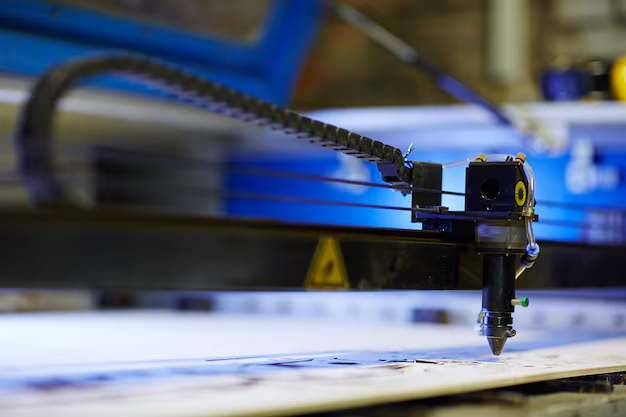

Future Form prides itself on using state-of-the-art equipment to deliver superior metal tube laser cutting services. The company's commitment to leveraging advanced technology ensures that clients receive the highest quality results tailored to their specific needs.

The use of modern machinery enables us to offer precision cuts with clean edges, reducing the need for additional finishing processes. This capability not only saves time but also enhances the overall quality of the finished product, providing clients with a seamless manufacturing experience.

Choosing Future Form for your metal tube laser cutting needs means partnering with a company dedicated to excellence and innovation. With a team of skilled professionals and access to cutting-edge technology, we deliver reliable solutions that meet the unique demands of each client. Whether you're involved in automotive design or constructing high-end architectural features, Future Form provides customized services that align with your objectives. The company's focus on precision manufacturing ensures that every project is executed with meticulous attention to detail.

In conclusion, metal tube laser cutting offers numerous benefits that make it an essential tool in precision manufacturing. From reducing material waste to enhancing design versatility, this technology provides significant advantages over traditional methods. Future Form stands out as a leader in this field, offering expert services that cater to diverse industrial needs. By choosing Future Form you gain access to top-quality laser cutting solutions that enhance your production capabilities and drive business success. For more information or to discuss your specific requirements, contact Future Form today. Let us help you achieve precision manufacturing excellence with our state-of-the-art metal tube laser cutting services.