As manufacturers, engineers, and product designers continuously seek advanced solutions for precision cutting, Future Form Manufacturing Sparks stands out with its state-of-the-art tube laser cutting services. This introduction will delve into how our tube laser cutting technology pushes the boundaries of manufacturing capabilities, ensuring high precision, automation and efficiency.

Our facility is equipped with advanced machinery that handles a plethora of materials and geometries, catering to a variety of industries. Whether your project requires precision tolerances or high volume output on tubes or pipes, our laser cutting services provide a blend of speed, precision, and versatility.

Why Choose Future Form for Your Tube Laser Cutting Needs?

Choosing the right partner for your manufacturing needs can dramatically impact the outcome of your projects. At Future Form, we are not only equipped with advanced tube laser cutting technology but also back our operations with decades of expertise. Our ability to handle custom orders efficiently makes us a cost-effective solution in the specialized sector of tube laser cutting. From prototyping to large-scale production, our services are designed to meet the rigorous standards required by modern industries and comply with our ISO 9001 certification.

We invite you to contact us to learn more about our custom tube laser cutting solutions, or visit our Sparks location for a personalized consultation. Sharing knowledge about our capabilities can help enhance understanding and application of this progressive technology in various fields.

High Precision and Efficiency

In the fast-paced world of modern manufacturing, precision and efficiency are not just desirable attributes—they are essential. At Future Form, we have harnessed cutting-edge technology and refined processes to meet these demands, offering our clients unparalleled product quality and performance. Our facilities employ advanced CNC machinery and robotic automation, which allow us to produce parts and products with extremely tight tolerances, ensuring consistent excellence time after time. Moreover, our emphasis on automation not only boosts our productivity but also reduces the margin for error, resulting in more reliable outputs across all product lines.

Quality control at Future Form is top-notch, involving rigorous testing and verification at various stages of production. We understand that high precision in manufacturing contributes not only to the satisfaction of our clients but also to the safety and reliability of the final consumers. By maintaining strict oversight through lean manufacturing and six sigma practices and employing advanced measurement tools, we can detect the lightest deviations, which are corrected promptly to adhere to the exacting standards required by our diverse clientele.

Innovations Driving Efficiency

Future Form continually strives to push the envelope in manufacturing technology. Our investments in research and development pay off by improving the efficiency of our processes, which in turn, enhances our competitiveness in the market. Automation has been a game-changer in reducing dependency on labor-intensive processes, thus speeding up production and minimizing costs. This transition not only streamlines manufacturing but also allocates human resources to more creative and critical tasks, fostering an environment of innovation and continuous improvement.

Moreover, we incorporate lean manufacturing principles to eliminate waste and optimize the workflow. Every step in our process is scrutinized for efficiency gains, from material selection through to final product assembly. The implementation of Just-In-Time (JIT) inventory practices is another facet of our operational procedures that ensures components are available when needed but do not accumulate excessively, which can tie up capital and increase overhead costs. These strategic initiatives enable us to maintain lean operations, reduce costs, and pass these savings onto our clients without compromising on quality or performance.

By integrating high precision and efficiency into every aspect of our operations, we not only meets but often exceeds customer expectations. This meticulous attention to detail and innovative approach to manufacturing position us as a leader in the industry, ready to face the challenges of today’s market dynamics and emerge as a preferred partner for businesses looking for reliability and excellence in their manufacturing needs.,

Versatility in Materials and Shapes

Our facility utilizes advanced technology and techniques to work with a multitude of materials, including mild steel, stainless steel, aluminum, brass, copper, & plastics. This capability allows us to cater to various industries - from automotive and energy sector products to electronics and consumer goods - making us a versatile and reliable partner. Flexibility in material choice not only meets specific industry standards but also opens up a world of innovation and customization for our clients.

In addition to material versatility, Futue Form also excels in offering an array of geometries and design options. Our state-of-the-art equipment, including CNC machinery and 3D printers, enable precision and complexity in design that traditional methods can’t match. Whether it's a turnkey medical device assembly or a custom-designed cabinet for a center build out, our commitment to versatile design and manufacturing options helps ensure that your exact customer needs are met.

Customization at Its Best

The ability to customize is key in today’s market, where differentiation often defines success. We not only provide standard products but also offer customized solutions that align with individual brand identities and functional requirements. This level of customization supports product uniqueness and customer satisfaction, leading to better market positioning and enhanced competitive edges.

Our team collaborates closely with clients to understand their needs and vision, translating these into tangible products with the perfect blend of material, shape, and function. From initial design to final production, our streamlined process is designed to deliver exceptional results with efficiency and precision. Moreover, our ongoing commitment to research and development means that we are continually expanding our capabilities and applying innovative techniques to keep you ahead in the market.

Therefore, whether you are a startup looking for niche market items or a large corporation needing high-volume production, Future Form has the flexibility and expertise to bring your projects to life. Our dedication to versatility in materials and shapes ensures that we are a one-stop shop for all your manufacturing needs, driving not only consumer satisfaction but also better search engine rankings as we boost your product visibility online.

Cost-Effectiveness of Custom Orders at Future Form

We understand that finding the right balance between cost and customization is crucial for our customers. When it comes to custom orders, many consumers wonder about the cost-effectiveness of tailoring a product to fit their specific needs. We are committed to providing not only creative solutions but also ensuring that these solutions are economically viable.

Custom orders allow for personalization that caters directly to an individual's or a company’s unique requirements. Whether it's a small tweak to an existing product or an entirely new design, custom solutions can often lead to better efficiency, improved performance, and ultimately, significant cost savings in the long run. By investing in a custom order, you are ensuring that you are not spending on features or capabilities that are irrelevant to your needs.

Strategic Benefits and Long-Term Savings

One of the primary advantages of choosing custom orders from Future Form is the strategic benefit these tailored solutions offer. For instance, businesses can optimize their operations by integrating custom parts that perfectly fit their machinery or system requirements, thereby reducing wear and tear and minimizing the need for frequent replacements. This tailored approach not only enhances the efficiency of operations but also extends the lifespan of the equipment.

Moreover, custom orders can adapt as your needs evolve, making them a flexible solution that can adjust to future requirements. This adaptability means that companies can avoid the costs associated with replacing entire systems when only minor upgrades are necessary. In the long run, this leads to substantial cost savings and a lower total cost of ownership, which is a crucial factor for businesses aiming to maximize their investment returns.

We take pride in our ability to collaborate closely with our clients. We invest time in understanding your exact needs and propose the most cost-effective solutions that do not compromise on quality or performance. Our team of experts uses their extensive experience and the latest technologies to design and manufacture products that not only meet but exceed our customers’ expectations.

W are dedicated to providing our customers with the most cost-effective custom order solutions available. We believe that customizing products to meet specific needs should not come at a prohibitive cost. By focusing on creating solutions that are both innovative and economical, we help ensure that our clients receive the best value for their investment. Our commitment to long-term partnerships and supporting our clients’ growth and efficiency with strategically tailored products distinguishes us in the industry.

Advanced Technology and Expertise at Future Form.

Embracing cutting-edge technologies and harnessing in-depth expertise are at the core of our business strategy. Our commitment to innovation is not just about staying competitive, but also about leading the way in our industry. We integrate advanced technology in various aspects of our operations to enhance product quality, improve operational efficiency, and deliver exceptional value to our customers.

Our state-of-the-art manufacturing facilities are equipped with the latest machinery and automation systems. This allows for precision engineering and production, ensuring that every product meets our high standards of quality and reliability. Moreover, our adoption of IoT (Internet of Things) technologies means that we can monitor production processes in real-time, anticipate maintenance needs, and minimize downtime, all of which contribute to a smoother, more efficient production line.

Expert Team Behind Our Innovations

Future Form doesn’t just invest in technology; we invest in people. Our team of engineers and technicians are among the best in the industry, with deep expertise in a range of technical fields. Regular training and development programs ensure they stay on top of the latest technological advancements and industry trends, enabling them to innovate and apply new techniques effectively.

Utilizing Expertise to Impact Consumer Needs

Understanding and anticipating consumer needs is vital, and our technologies help us achieve just that. By using advanced data analytics, we can better understand consumer behavior and preferences, which allows us to tailor our products and services accordingly. This data-driven approach to business helps us maintain a strong connection with our customers and ensures we are always ahead of market trends.

Furthermore, our commitment to using sustainable technologies reflects our responsibility towards the environment and our consumers. We aim to reduce our carbon footprint and promote sustainability in our production processes, which directly impacts and benefits our clientele by providing them with eco-friendly choices.

At Future Form, we believe that our combination of advanced technology, comprehensive expertise, and a deep understanding of consumer needs sets us apart in the marketplace. It is with these tools that we continue to provide top-quality products and achieve high customer satisfaction rates, ultimately boosting our search engine rankings and reaching a broader audience.

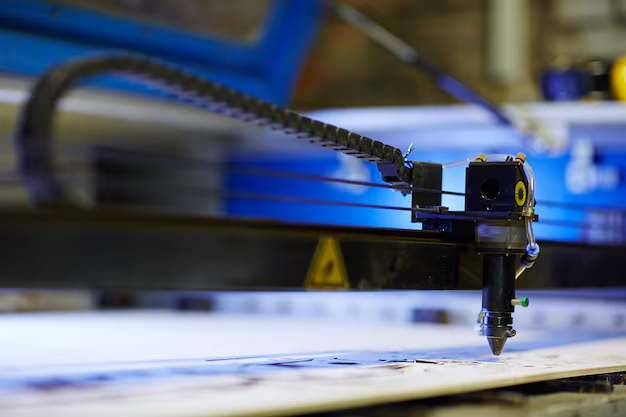

In the world of precision manufacturing, metal tube laser cutting stands out as a revolutionary process that offers unparalleled accuracy and efficiency. Future Form Manufacturing is at the forefront of this technology, providing top-tier services that cater to diverse industrial needs. This article explores the many benefits of metal tube laser cutting and why Future Form is your go-to partner for these services.

One of the primary advantages of using a metal tube laser cutting machine is its ability to deliver exceptional precision and accuracy. This technology ensures repeatable results, making it ideal for industries where tight tolerances are critical, such as aerospace, automotive, and medical equipment manufacturing. By utilizing computer-controlled lasers, we can achieve intricate designs with minimal errors, ensuring that each cut meets exact specifications. The precision offered by laser cutting not only enhances product quality but also reduces the likelihood of defects. This level of accuracy is particularly beneficial in applications where even minor discrepancies can lead to significant issues. Whether it's creating complex geometries or executing detailed patterns, our laser cutting services ensure consistent excellence.

Another significant benefit of metal tube laser cutting is its ability to minimize material waste. Traditional cutting methods often result in substantial scrap material, which can increase costs and negatively impact sustainability efforts. However, laser cutting creates narrow, precise cuts that maximize material use and reduce waste. Future Form employs advanced nesting technology to ensure efficient material utilization, aligning with sustainable practices and contributing to cost savings. By minimizing waste, businesses can optimize their resources and improve their environmental footprint, making laser cutting an attractive option for companies committed to sustainability.

Metal tube laser cutting machines offer remarkable versatility, accommodating a wide range of materials including steel, aluminum, and copper. This flexibility extends to handling various shapes and profiles, enabling the creation of intricate designs that traditional methods cannot achieve. We leverage this versatility to serve clients across multiple sectors such as transportation, medical infrastructure, exercise equipment and electronics. The ability to adapt to different materials and designs allows businesses to explore innovative solutions and expand their product offerings without compromising on quality or efficiency.

Cost efficiency is another compelling reason to choose metal tube laser cutting. By reducing the need for manual intervention and streamlining production processes, this technology lowers labor costs and accelerates production timelines. Automation also facilitates continuous operation, enabling businesses to meet tight deadlines without sacrificing quality. At Future Form, the integration of automation with laser cutting technology ensures that projects are completed efficiently and economically. This approach not only reduces operational costs but also enhances productivity, allowing businesses to maintain a competitive edge in the market. Future Form has invested in a nitrogen generator that further reduces operating cost by utilizing ambient nitrogen instead of purchasing and vaporizing liquid nitrogen to supply the required cutting gas.

Future Form prides itself on using state-of-the-art equipment to deliver superior metal tube laser cutting services. The company's commitment to leveraging advanced technology ensures that clients receive the highest quality results tailored to their specific needs.

The use of modern machinery enables us to offer precision cuts with clean edges, reducing the need for additional finishing processes. This capability not only saves time but also enhances the overall quality of the finished product, providing clients with a seamless manufacturing experience.

Choosing Future Form for your metal tube laser cutting needs means partnering with a company dedicated to excellence and innovation. With a team of skilled professionals and access to cutting-edge technology, we deliver reliable solutions that meet the unique demands of each client. Whether you're involved in automotive design or constructing high-end architectural features, Future Form provides customized services that align with your objectives. The company's focus on precision manufacturing ensures that every project is executed with meticulous attention to detail.

In conclusion, metal tube laser cutting offers numerous benefits that make it an essential tool in precision manufacturing. From reducing material waste to enhancing design versatility, this technology provides significant advantages over traditional methods. Future Form stands out as a leader in this field, offering expert services that cater to diverse industrial needs. By choosing Future Form you gain access to top-quality laser cutting solutions that enhance your production capabilities and drive business success. For more information or to discuss your specific requirements, contact Future Form today. Let us help you achieve precision manufacturing excellence with our state-of-the-art metal tube laser cutting services.

When it comes to securing reliable and high-quality welding in Nevada, Future Form manufacturing stands out as a premier provider. With an extensive background in a multitude of welding projects, Future Form offers unmatched expertise and a robust range of services designed to meet the diverse needs of both individuals and businesses. Whether you require assistance with a minor repair or are embarking on a large-scale construction project, our dedicated team is equipped to deliver top-notch results.

Future Form prides itself on a foundation of extensive experience and a deep commitment to quality and safety. Our decades of expertise, coupled with our customer-centric approach, ensure that every project is handled with precision, care, and efficiency. Whether you're in need of custom fabrication, repair services, or specialized welding work, we have the tools and talent to exceed your expectations.

At Future Form in Sparks, our extensive experience and in-depth expertise distinguish us in the competitive market. For over three decades, we have been dedicated to providing high-quality products and services that meet the diverse needs of our customers. Our team comprises seasoned professionals who possess a rich blend of knowledge and skills, developed through years of hands-on experience across multiple industries.

This expertise is widespread across all levels of our organization. Every team member is rigorously trained and continuously educated on the latest industry trends and technologies. Our commitment to professional development ensures that we stay ahead of industry changes, providing innovative solutions and reliable products for all our clients.

At Future Form, excellence is not just an objective—it’s a driving force. Our processes are regularly assessed and updated to ensure precision in production and efficiency in service delivery. By maintaining high standards and understanding our clients' specific needs, we’ve built lasting relationships with both customers and suppliers, allowing us to respond swiftly to market demands.

Located in the vibrant industrial community of Sparks, Nevada, Future Form provides a comprehensive suite of services tailored to meet the needs of both local and national clients. Our offerings include custom manufacturing, advanced engineering solutions, and complete supply chain management, all designed to enhance operational efficiency and reduce costs.

Our custom manufacturing capabilities stand out as a key service. Whether you need a unique piece of machinery, precision aerospace parts, or specialized equipment for the medical industry, our expert team uses cutting-edge technology to deliver exceptional results. In addition, our engineering expertise ensures that we’re not only manufacturing products but also optimizing them for performance, sustainability, and cost-effectiveness.

Beyond manufacturing, our engineering team specializes in product development, process improvement, and automation, working closely with clients to deliver custom solutions that meet their specific requirements. Our use of advanced software, 3D CAD modeling, and AI-driven automation ensures our services remain at the forefront of innovation.

Incorporating the latest technological advancements into our operations, we also provide transparent and efficient supply chain management solutions. These innovations streamline processes and ensure that our products and services are delivered on time, maintaining the trust and satisfaction of our clients.

In today’s competitive market, Future Form understands that customization and flexibility are essential. By focusing on tailored solutions, we not only meet but exceed customer expectations, driving satisfaction and loyalty. Our personalized approach empowers customers to design products and services that fit their specific needs, enhancing both user experience and our online presence.

Leveraging data analytics and market insights, we offer innovative solutions that keep us responsive to evolving demands. By promoting our custom services digitally, we improve our SEO outcomes, driving more traffic and enhancing engagement with our content.

Safety and quality are the cornerstones of our business. We implement rigorous testing protocols and quality control measures at every stage of production, ensuring that each product meets or exceeds industry standards. Our facilities are equipped with sophisticated monitoring systems to maintain optimal production environments, while our commitment to employee safety includes comprehensive training and regular safety drills.

We continuously invest in technological advancements and training programs to enhance our capabilities and maintain our competitive edge. By fostering an environment of continuous improvement, we ensure that both our staff and our products evolve with industry standards.

Future Form Manufacturing is your trusted partner for expert welding services, custom manufacturing, advanced engineering, and supply chain solutions. Our commitment to safety, quality, and customer satisfaction ensures we deliver outstanding results on every project. Contact us today to learn more about how we can support your business and bring your vision to life!